-

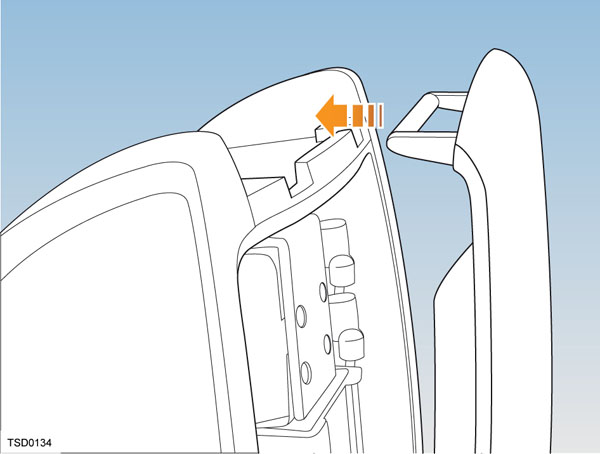

Charge port door

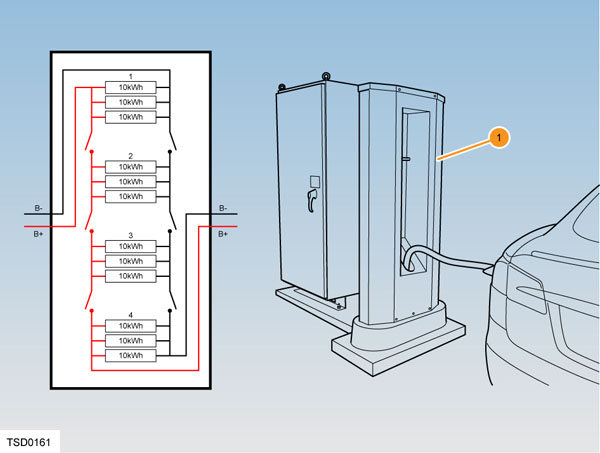

Position the vehicle as close as possible to the electrical outlet. The charging cable must be able to easily reach the charge port without putting a strain on either the electrical outlet or the charge port.

-

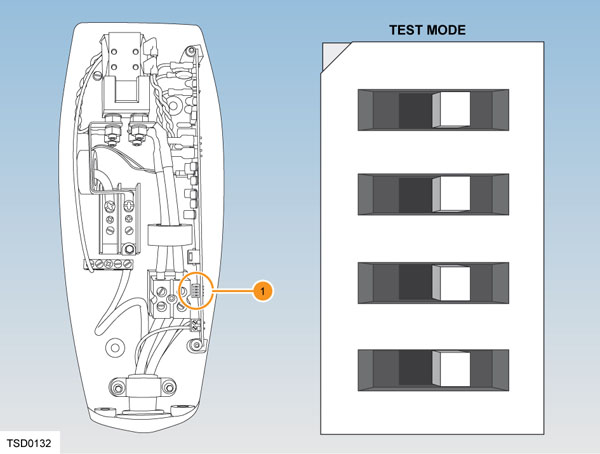

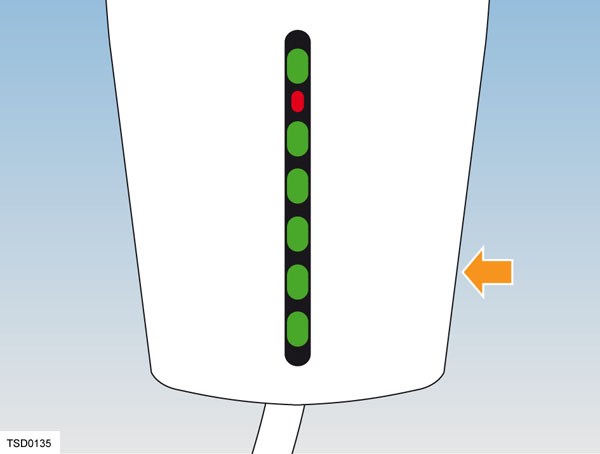

The indicator LED on the unit should turn green to indicate that the unit is operating correctly and is ready to be connected to the vehicle.

-

If the indicator LED turns red, a fault has been detected. A fault might occur if it is plugged into a faulty outlet. Unplug and visually inspect the outlet. If no indicator is seen, the outlet might not be powered.

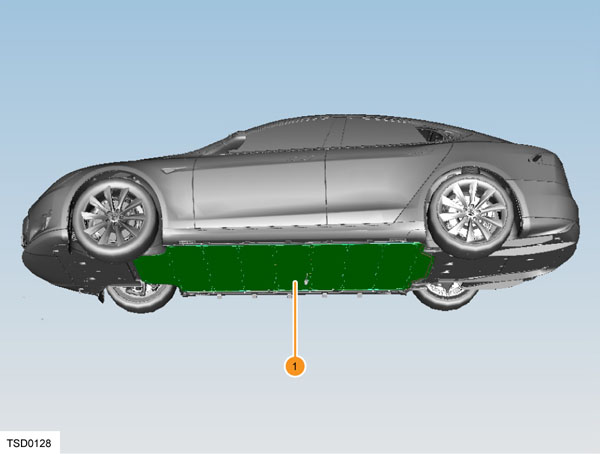

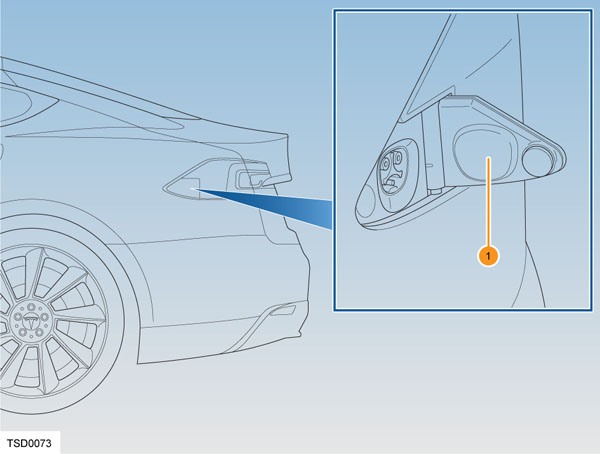

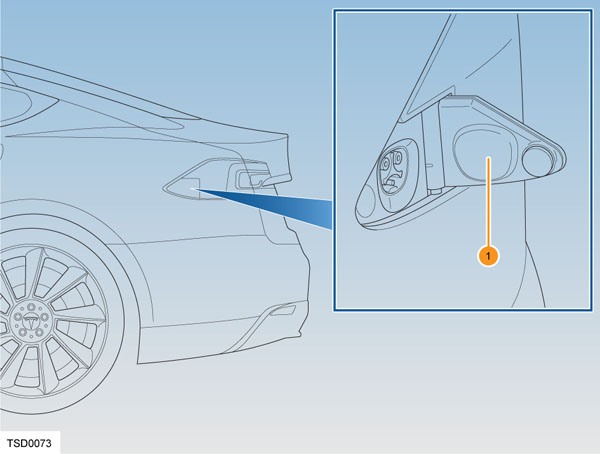

The charge port is located on the driver’s side behind a door which is part of the tail light assembly.

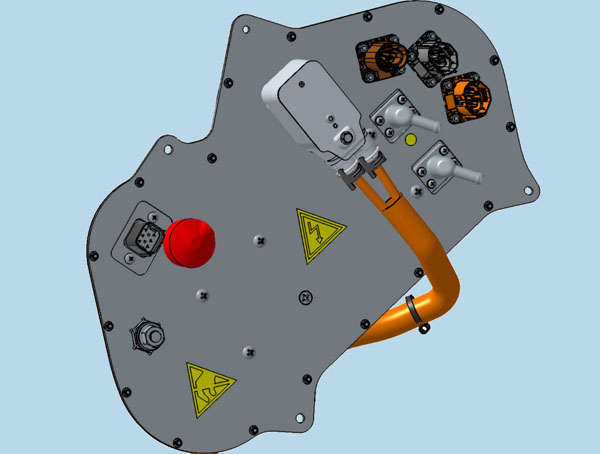

NOTE: The charge port door harness has a proximity signal resistor. If this fails, the car cannot be charged. There is also a proximity resistor in the charge connector. If the proximity in the charge connector is bad, the charge port latch does not raise to lock the connector in place.

When the charge connector is powered, pressing and holding the button on the connector sends a wireless signal to the vehicle to open the charge port door and drop the latch. The vehicle must be unlocked or have a recognized key in range for the charge port door to open. If the vehicle has poor reception, try aiming the connector at the back window of the car.

If you are not using a Tesla charging cable, touch CONTROLS > CHARGE PORT on the touchscreen.

NOTE: The light ring around the charge port glows white when the door is open. If a charging cable is not connected, the latch raises after a time-out period of 5 minutes. If this happens, simply press the button on the charge connector again, or touch Unlock Charge Port on the touchscreen charging information screen.

Align the charging connector to the charge port and insert fully. A latch engages automatically to retain the connector. The car does not enter drive mode while a connector is plugged into the charge port.

Once charging starts, the light ring on the charge port flashes green. If the light ring is pulsing yellow, charging current is limited to 16 amps. The most likely cause is the charging connector not being fully seated in the charge port, which prevents the latch from engaging the connector. Remove the connector from the charge port and reconnect it, ensuring it fully seats in the charge port.

If the light ring turns red, a fault has been detected. Refer to the touchscreen to see if more specific fault information is provided.

-

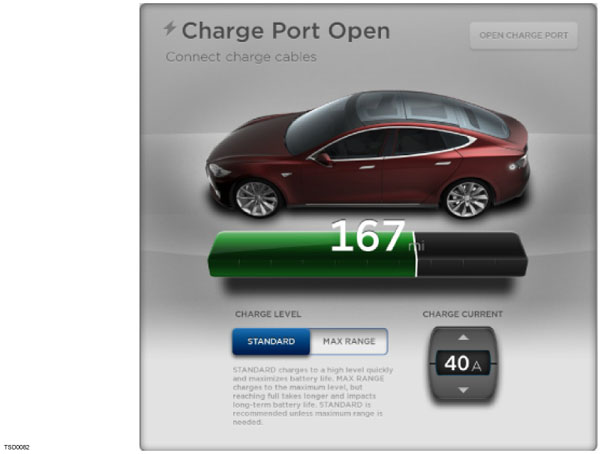

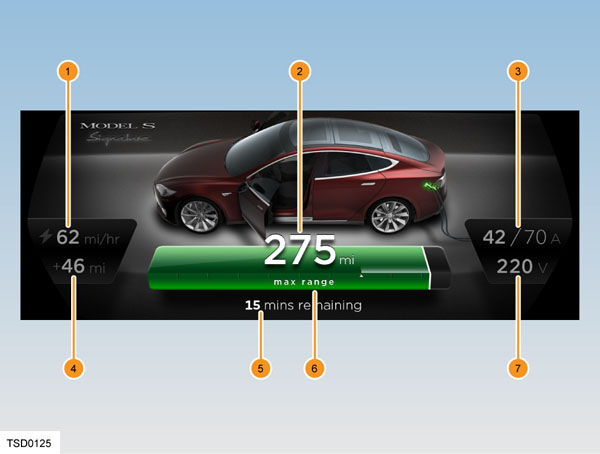

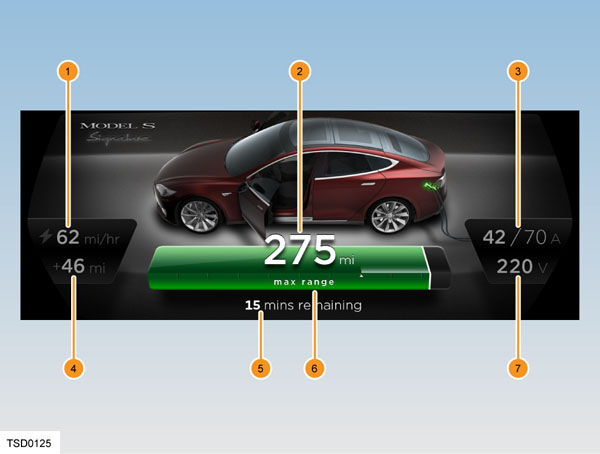

Charging rate per hour

-

Vehicle range

-

Charging current/maximum current available from supply

-

Range increase this charging session

-

Time remaining until charged

-

Charge level

-

Voltage of supply

The instrument panel displays the current charging information.

As the Battery nears a full charge, the pulsing of the charge port ring slows down. When charging is complete, the pulsing stops and the ring turns solid green.

When charging is complete, or to interrupt charging, push the button on the connector to release the charge port latch. The latch clicks as it disengages. Continue holding the button down and remove the cable from the charge port.