(Built for, and tested on, 1989 Aerostar 3.0l; it is assumed that it will work for the 2.3l and 4.0l, but I'd appreciate feedback from folks who try it on those engines.)

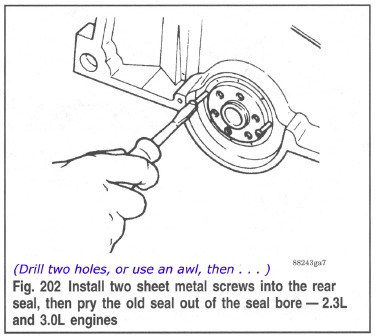

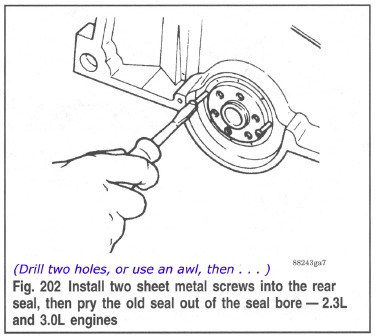

The problem: These engines use a modern, full lip seal, which is easily removed:

Here's what Ford & Chilton's recommend:

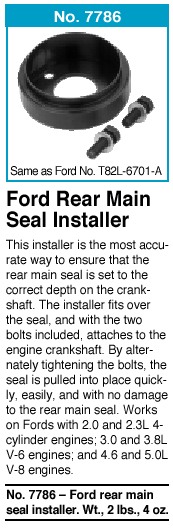

The

problem is that this tool is fairly expensive. The OTC equivalent

is No. 7786, and runs nearly $100 (sourced via NAPA, without discounts)

The

problem is that this tool is fairly expensive. The OTC equivalent

is No. 7786, and runs nearly $100 (sourced via NAPA, without discounts)

Faced with this, and not wishing to lay

out $100 for a (I certainly hope!) one-time-use tool, I visited my hardware

store and started brainstorming. As usual, the plumbing section was

very useful.

This picture contains:

I also needed a 27/64" drill bit ($7) (see below).

The seal's OD is close to 4.25"

The pipe plug's OD is close to 4.375"

4" ABS is about 4.5" OD

When I was at the hardware store dreaming

this up, I wasn't certain how much clearance around the seal I'd have.

For the 3.0l engine, it looks to be a safe bet that you could use a section

of pipe, or a different fitting, rather than a pipe plug, and this might

buy you more "throw" -- more on this later.

10mm = .394", roughly. The crank's bolt pattern is asymmetric, and I'm not exactly using precision equipment for the hole layout, so I want a nice, loose fit for the draw-in bolts. I used a 27/64" bit (.422"), yielding almost .030" slop. That should be enough :) If your drill index doesn't include a 27/64" bit, well, 7/16" is only .016" larger, and should be fine.

I began by using the long bolts I purchased (and the flat washers to effectively make the bolts shorter), to pull the seal into place. When the long bolts bottomed out in the crankshaft, I switched to the OEM bolts to draw the seal in further. The "throw" of this tool is just a smidge over 1/2", which was enough for the 3.0l seal installation; I assume that the 4.0l seal, which must be pressed in below flush by about .413", might require some careful "finish work" with a suitable punch.

I found that the tool cocked slightly,

but that tapping the non-bolt quadrants a bit (that is, the sides of the

cap that do not have bolts) corrected that. I also switched the bolts

to different holes, which helped.

A very poor picture:

|

The finished result:

|

A $20 tool that did the job for me.

Comments to Al Savage

-- end