John Savage pipe organ

3-26-2001 W.W.

Kimball 2 manual / 4 rank pipe organ

was dismantled, packed and loaded

into 15 ft truck to be moved

from Los Angeles to Tennessee -

used "Pipe trays" obtained from

local pipe organ builder

[pipe trays 97]

For over 20 years a pipe organ hid out here

on this private street with no street lights - great setup for halloween.

[Home 98]

The new owner: Evans Baird - trying out his purchase

[Evans Baird 99]

Evans Baird ( left ) and John Frisk (right) unsoldering wiring

from back of console

this organ has about 400 pipes and as many or more wires. Switch

stack is on the

backside on console. Note the 12 vdc solid state power supply

for magnets in

lower right corner of console. In 1937 the organ used a generator

connected

to a Spencer turbine blower for the DC power.

[Legs 101]

Console disconnected and moved out of area.

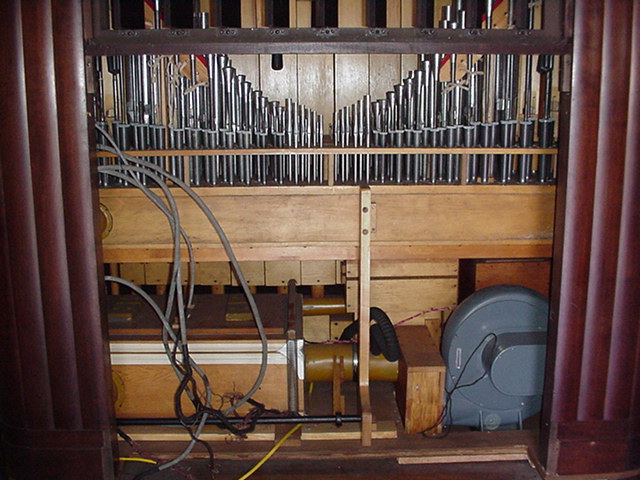

Upper edge of view - opened swell shades

Under 4 rank wind chest is: regulator (left) / Tremulant (center) /

blower (right)

Black hose between blower and regulator would connect to console

14 note offset chest in rear - foundation pipes

[organ 102]

1 Hp Meidinger blower ( 1978 ) 240 VAC single phase

Original Spencer blower was too large to fit inside organ case and

was noisy

[blower 103]

Switch stack on backside of console - wind line hose connects to yellow

pipe

on action box upper edge of picture - 3 ranks of switches flush mounted

and

4th rank ( oboe ) bank of switches is lower right corner - surface

mounted.

[switch stack]

Console and pedal board was moved AT THE SAME TIME

because the pedal board cable is still connected to console !!

[console 104]

[move 105] That loading ramp got a lot of use.

John Frisk (left) and Evans Baird (right)

[the crew 106]

Evans packing oboe pipes in pipe tray

[packing oboe 108]

[J.Frisk 109] transport oboe pipe out for packing

Packing flute pipes in pipe tray

[flute 110]

Note 1-1/8" thick sub floor plywood panel with casters under it - on

lawn -

Console & pedal board sets on that section of platform

[packing 111]

Rear of pipe chamber - with chamber panels and pipes removed.

Original wind lines in this organ are also made out of pipe metal material

same

as metal organ pipes. Lower/left corner is air intake with

filter removed.

Pipes used at left end have very tall "toes" as originally manufactured

so wind line may be threaded between them to wind the organ.

Since there were no holes anywhere in casework, this organ was winded

through the floor in all previous installations. I built the

existing intake

wind line box - felt lined - to eliminate air noise - to fit between

those two organ pipes with tall "toes" as I installed the blower inside

chamber.

[chamber rear 112]

Note: 1-1/8 inch thick sub floor plywood platform - on casters - enables

organ to

be moved after assembly. Blower sets into step down area in platform

[empty chamber 113]

lower right corner - moving console platform (with casters) towards

truck

I had added fluorescent lamp - The inside chamber case is a dark cave

otherwise

[console platform 115]

Judy is happy - more space in home

[Happy wife 117]

Organ is out of the home - this bookcase and section of floor has not

been seen

for 20 years.

[hidden bookcase 118]

Return to home page Return to top

Thank you for taking the grand tour.